Welcome to our informative post, “Exploring The Flammability of New Air Conditioning Refrigerants”. This detailed guide will provide you with a comprehensive overview about the flammability potential of various types of air conditioning refrigerants currently present in the market. It’s not just a technical review, it’s an educational insight offering key information about emerging technologies, and best practices, that can assist you in making safer, and more environmentally friendly choices. Leveraging expert opinions and fact-based evidence, this post aims to enlighten you on this significant aspect of HVAC systems, ultimately empowering you with valuable knowledge that can contribute to improved safety and efficiency in your home or workplace. Whether you’re a homeowner, a professional in the HVAC field, or someone simply interested in understanding more about air conditioning refrigerants, this post has plenty to offer. So, let’s deep dive into this important, yet often overlooked aspect of cooling technology.

Understanding the Importance of Flammability in New Air Conditioning Refrigerants

With the growing concerns over climate change and increasing regulatory compliance, air conditioning refrigerant manufacturers are consistently developing new, environmentally friendly refrigerants. An important element in the development and utilization of these new refrigerants is understanding their flammability characteristics. Some refrigerants being developed may be less harmful for the environment, but have higher flammability compared to traditional types. Understanding this trait is crucial when evaluating their safety and applications.

Comparative studies conducted on a variety of new generation refrigerants show significant variation in their flammability. This doesn’t imply they should be discarded, but reinforces the need for appropriate application and risk analysis.

| New Generation Refrigerant | Classification of Flammability |

|---|---|

| Hydrofluoroolefins (HFOs) | Medium to High |

| Hydrocarbons (HCs) | Very High |

| Natural Refrigerants | Low to Medium |

It is essential to remember that although a type of refrigerant may have a higher flammability, safety measures included in commercial air conditioning systems are designed to prevent this from being a significant risk. Even more, safety and performance standards are continually being updated to accommodate this rise in flammable refrigerants in a safe and efficient manner.

Incorporating the right safety measures and operational parameters can make the usage of these newer, flammable refrigerants safe. Some of these include leak detection systems, installation guidelines and training for service technicians.

- Leak detection systems: These systems identify and mitigate risks associated with potential refrigerant leaks.

- Installation guides: To promote safe handling and risk reduction, clear and detailed installation guidelines are necessary.

- Technician training: Ensuring service personnel are updated with the latest safe handling procedures for new refrigerants is of paramount importance.

Understanding the flammability rules of new refrigerants is a key step in the journey towards a more environmentally friendly and efficient air conditioning industry. By employing industry standards and regulations, the risks can be appropriately managed ensuring safety and comfort for all users.

Evaluating Flammability Risks in New AC Refrigerants: An In-depth Look

New generations of air conditioning refrigerants are typically designed to be safer, more efficient, and less harmful to the environment. However, like any other chemical substance, they come with their own share of potential hazards, one of which is flammability. Flammability refers to a substance’s tendency to ignite and the potential for fire to spread if ignition occurs. This post explores the subject in the context of new AC refrigerants.

Key factors for evaluating flammability risks include:

- Flammable range: This is the concentration range between the lower and upper flammable limit at which the refrigerant can ignite. Depending on the chemical components, some refrigerants have a larger flammable range than others.

- Ignition temperature: The minimum temperature at which a refrigerant can ignite in the presence of an ignition source.

- Heat of combustion: It is the amount of heat released when a substance is burned in an excess of oxygen.

These are just a few examples; the complete list can be much more in depth and complex. Experts rigorously test these and other parameters to ensure safety. However, while these new refrigerants can be assessed and controlled under laboratory conditions, it is important to remember that real-life situations may be unpredictable and present additional challenges.

A table showcasing some common new refrigerants and their key flammability attributes is shown below.

| Refrigerant | Flammable Range | Ignition Temperature | Heat of Combustion |

| R-32 | 13.3 – 29.3% (Air) | 420°C | 5,460 kJ/kg |

| R-1234yf | 6.2 - 12.3% (Air) | 405°C | 5,360 kJ/kg |

| R-1234ze | 7.0 – 9.5% (Air) | 410°C | 5,380 kJ/kg |

Keep in mind that understanding and managing the flammability risks of AC refrigerants requires knowledge and training. Always use refrigerants as directed and consider consulting a professional if you have any questions or concerns.

Expert Analysis: How Flammable Are New Generation Air Conditioning Refrigerants

In the world we live in today, the need for cooler indoor air has never been greater due to global warming. As a result, scientists have been working round the clock to invent new generation air conditioning refrigerants which are more environment-friendly and effective. However, a major concern addressed by numerous experts is their flammability. How flammable are these new generation air conditioning refrigerants?

The pertinent question remains, what are the factors influencing the flammability of these refrigerants? Three major considerations should be noted. Firstly, the chemical composition of the refrigerant often determines its flammability. Hydrofluoroolefins (HFOs), commonly used in these new generation refrigerants, do exhibit flammable characteristics under certain conditions. Secondly, flammability is greatly influenced by temperature and pressure conditions. High pressure and temperature conditions increase the flammability of these refrigerants. Last but not least, the presence of ignition source plays a role as flammable refrigerants will not ignite without an ignition source.

| Type of Refrigerant | Flammability Level | Risk |

|---|---|---|

| Hydrofluoroolefins (HFOs) | Moderate | High under certain conditions |

| Hydrofluorocarbons (HFCs) | Low | Low |

Modern air conditioning systems have been designed with safety mechanisms to mitigate the risks posed by flammability. However, recent incidents related to refrigerant leakages emphasize the importance of routine checks and maintenance to ensure these safeguards are functioning properly. While the search for the perfect refrigerant continues, it is important to enhance the safety measures and precautions when dealing with these new generation refrigerants.

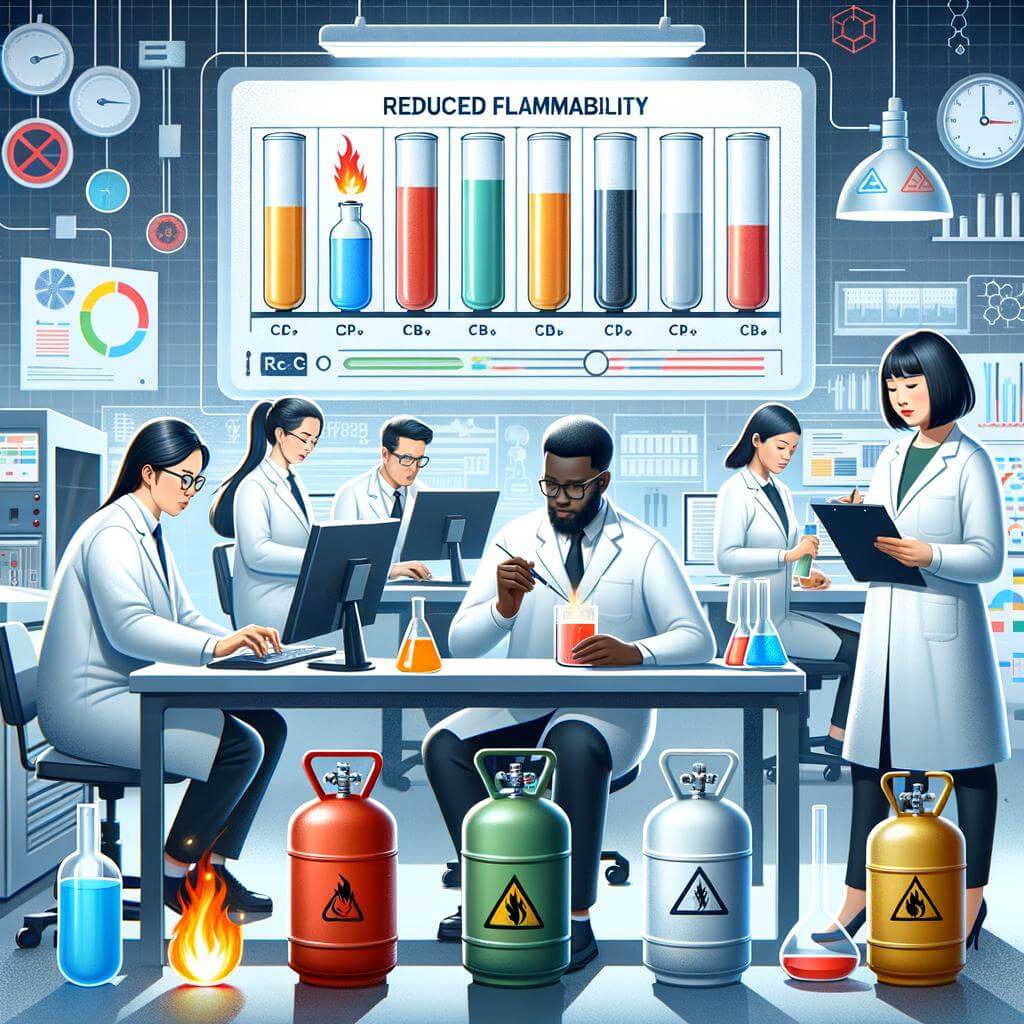

Providing Safe Solutions: Reducing Flammability in New Air Conditioning Refrigerants

As the refrigeration industry continues to innovate and evolve, an essential part of the consideration is safety. Therefore, the industry is actively conducting research to reduce the flammability of new air conditioning refrigerants. Traditional refrigerants such as HCFCs and HFCs not only have high Global Warming Potential (GWP) but also pose flammability and toxicity risks. With the focus on greener and safer alternatives, manufacturers are assessing various low-GWP alternatives, including hydrofluoroolefins (HFOs) and natural refrigerants such as CO2 and ammonia.

Understanding Flammability Classes

In order to evaluate the safety of these new refrigerants, it’s crucial to understand the flammability classes established by the American Society of Heating, Refrigerating and Air-Conditioning Engineers (ASHRAE). Accordingly, the ASHRAE classifies refrigerants into three broad categories based on their ignition and heat energy: class 1 (no flame propagation), class 2 (lower flammability), and class 3 (higher flammability).

| ASHRAE CLASS | FLAMMABILITY LEVEL |

|---|---|

| Class 1 | No flame propagation |

| Class 2 | Lower flammability |

| Class 3 | Higher flammability |

Various alternative refrigerants currently under investigation belong to the Class 2 and Class 3 categories. Despite these categories’ implied higher flammability, it’s important to note that many factors can influence a refrigerant’s real-world flammability risk. These aspects include system design, charge size, leak size, and leak rate. As a result, manufacturers are exploring ways to manage these factors and mitigate the risk without compromising performance or environmental benefits.

Mitigation Techniques

- By reducing leak sizes through enhanced system design and manufacturing processes.

- Minimizing the charge of refrigerant through advanced technology and system optimization.

- Installing leak detection and system shut-off mechanisms to prevent accumulation of refrigerant in an enclosed space.

While there’s still a long way to go in terms of fully understanding these new refrigerants’ safety dynamics, extensive research, trials, and improvements in design and manufacturing processes are promising. The goal is to provide air conditioning solutions that are not only efficient and environmentally friendly but also offer safe operation in a myriad of conditions and applications.

Innovative Approaches to Minimize the Flammability of Air Conditioning Refrigerants

Understanding the flammability of new air conditioning refrigerants has become a necessary concern for those with an interest in the HVAC-R industry. One of the innovative approaches of minimizing flammability in this context involves the application of a flammability suppression system. This is based on the principle of using materials that hardly support combustion to retard or suppress the flammability of the refrigerants. With the advent of cutting-edge technologies, the problem is gradually becoming manageable via the utilization of flammability suppression systems with low Global Warming Potential (GWP).

The second approach that can be applied to reduce the flammability of A/C refrigerants is the implementation of blending techniques. This involves the strategic combination of refrigerants to obtain a blend with significantly lower flammability. In many instances, non-flammable refrigerants are blended with low-GWP, but highly flammable working fluids to make much safer alternatives. These approaches have marked a pivotal turning point in the air conditioning industry by balancing operational safety and environmental friendliness.

Below is an illustration of these two innovative approaches:

| Method | Description |

|---|---|

| Flammability Suppression System | Works by suppressing the flame or fire source in order to prevent a higher rate of burn. This reduces the overall flammability of the refrigerants. |

| Blending techniques | This approach lowers the flammability of high-GWP refrigerants by incorporating non-flammable materials in the blend, therefore, offering a safer option. |

Recommendations for Choosing Less Flammable Air Conditioning Refrigerants

When selecting refrigerants for your air conditioning system, there are specific characteristics you should prioritize to maximize safety. Primary among these is the flammability factor. Not all types of refrigerants are created equal in this regard. Some are inherently less flammable, reducing the potential risk of fire in your AC system.

Some practical suggestions in your search for less flammable AC refrigerants include:

- Carefully read product specifications: Manufacturers are obliged to offer detailed product specifications. These should highlight the flammability rating of each refrigerant.

- Consult with HVAC professionals: If you’re uncertain, speaking with an HVAC technician can provide valuable insights into the best, less flammable refrigerant options.

- Consider Quality over Cost: Investing in high-quality refrigerants may require additional initial costs but can save you potential risks and expenses in the long run.

| Refrigerant | Flammability Rating |

|---|---|

| R-410A (Puron) | Class 1 (No Flame Propagation) |

| R-32 | Class 2L (Lower Flammability) |

| R-290 (Propane) | Class 3 (Higher Flammability) |

Bear in mind, the selection of air conditioning refrigerants should not rely solely on their flammability ratings. Also consider other factors such as effectiveness, environmental impact, and energy efficiency for an all-round superior choice.

To Wrap It Up

In conclusion, understanding the flammability of new air conditioning refrigerants is paramount not only for the safety of our homes but also for the environment. The insights offered aim to shed light on the potential risks involved and the need for regular and professional maintenance. Another key takeaway is the importance of investing in high-quality equipment and using approved refrigerants, which offers the dual benefit of reduced environmental impact and improved safety. We believe that with the right approach, focus on safety norms, and a bit of knowledge, everyone can contribute to making the world a safer and cleaner place. Keep exploring, keep learning, and remember – a well-informed decision is the best preventive measure.